Weight instrument

Weight instrument

Weight instrument

It is used to convert the weight into an analogue electrical quantity, which is fed to the PLC to display it on the screen.

Its applications: knowledge of weights and loads and controlling their quantities.

Weighing cells should be attached to an amplifier to give an alarm in case of imbalance of the weighing according to the application.

Specifications for Weight instrument (transferred):

Accuracy Class

It is symbolized by the symbol “Class III”, C3, C4, C5, or C6, classified as 1:4000, or 1:5000, or “Class IIIL”, classified as 10000:1 for the commercial weight. This ratio is used by knowing what the kilogram represents of the signal, and thus knowing the lowest possible scale. On it with the stability of reading the display of the weight statement

- Rated Capacity

It is denoted by the symbol “kg” which means kilograms, “ton” which means a ton, or “Ib” which means a pound or “kib” which means 1000 x pounds. More than 80% of the recorded weight, noting that all weighing cells can operate 150% of the weight written on them without damage and the maximum weight that damages the cell mechanically (stress 200% or greater in some weighing cells

- Input Impedance value

It is symbolized by the symbol “Ω”. Common Weight instrument have a resistance of 350 Ω, 610 Ω or 700 Ω. The higher the value of the resistance, the greater the electrical resistance ( ) that the cell draws. Therefore, a larger number of Weight instrument can be installed on the weighing device.

- The value of the resistance of both ends of the signal “Output Impedance”

It is symbolized by the symbol “Ω”, which is the same as Item No. 3, with a slight difference in value within the limits of 5% less

Execution

It is symbolized by the symbol (V) and the feeding voltage ranges from 5 volts to continuous or alternating current. The greater the value of the feeding voltage, the greater ( ) is represented by a kilogram of the output signal. On the other hand, we find that the large feeding voltage negatively affects the Foil Strian Gauge and reduces its life ( )

Rated Output

It is symbolized by the symbol (Mv), which is the value corresponding to each volt of feed, i.e. “MV/V” and there is a standard for that such as 3MV/V-4MV/V” ( ) and the higher this value, the greater the value represented per kilogram gives stability to the reading of the weighing screen and we find some companies ( )

The output is 1.5MV/V or 2.5MV/V, and this is considered a major defect that falls under the name of monopoly, as it is difficult to obtain replacement cells for the Weight instrument in the weighing system, which obliges the owner of the scale to resort to this company to buy a replacement for the damaged ones, and in most cases the prices are exaggerated

- Temperature “Compensated Temperature Range”

It is defined by the range of temperatures at which the cell operates while maintaining the error percentage stipulated in the calibration report attached to ( ) Weight instrument. The range is -18: +40 degrees Celsius. There are cells operating in the range of +65: -18 degrees Celsius. The error percentage for each degree can be known. Celsius if it exceeds that range and is explicitly stated under the name “Temperature Effect On Sensitivity”

- The isolation ratio “Seal Type”

It is symbolized by the symbol “IP” and represents the percentage of isolation “Strain Gague” from the surrounding atmosphere of the cell. There are IP65-IP67-IP58 among them, and the higher the number, the better it will withstand bad weather conditions.

Combined Error value.

The percentage of the accumulated error includes “Creep Error” and the “Hysteresis” value, and it ranges from 0.01% to 0.5%, and the lower the value of this number, the better.

- The type of metal for the cell body “Element Material”

Weight instrument are available in three types: aluminum (the cheapest), steel, or stainless steel (the most expensive).

The structure of the cell

Weighing cells are available in many forms, including cylindrical, rectangular cube or letter S, and the shape is chosen according to the type of application

Manufacturing and classifying weighing cells as one of the measuring elements used to measure solids and minerals of all kinds

Manufacturing and classifying weighing cells as one of the measuring elements used to measure solids and minerals of all kinds

Manufacturing and classifying weighing cells as one of the measuring elements used to measure solids and minerals of all kinds

Manufacture and classification of weighing cells of all kinds from the measuring elements used to measure solid materials in general and their types in particular:

Weight instrument consist of three main components:

Weight instrument body

Metal strain gauge.

Cell extension cable.

First, the body of the Weight instrument (metal):

The metal from which weighing cells are made is the most important component of weighing cells. Where the metal expands or shrinks by the amount of force it is exposed to in a direct relationship, so if the metal is subjected to a weight of its amount, it expands or shrinks by an amount and the relationship between them is soft, according to Hooke's law, which states that the elongation is directly proportional to the amount of weight or force on the body of the metal.

By practical experiments, a curve was obtained for each mineral called sTREES cURVE sTRAIN, and this curve consists mainly of two regions.

The first region: It is called the elastic region, and this region expands or contracts at a fixed rate that is directly proportional to the amount of force applied to it, and the instrument returns to its original state when the force or weight affecting it is removed. If we look at the curve, we find that the expansion coefficient of the metal in this way is at a regular and constant rate and its rate is a straight line from the first state.

The second region: it is called the plastic region, and this region expands or shrinks at a rate that is not fixed and is directly proportional to the amount of force applied to it. Second degree. If the force increases by a certain amount, we find that the metal reaches the point of fracture.

And there is no secret in the material of the Weight instrument. Where it is possible to manufacture a cell of any kind of minerals, but the difference between minerals and each other is in the difference in increasing the dotted area, as the soft metal has a small area and vice versa in the hard metal.

From 2-10 square millimeters, thin wires with an electrical resistance of 120 or 350 (without stress) are attached to them. The value of this resistance changes directly proportional to the amount of expansion, contraction or curvature of this thin slice. It is called “foil strain gauge”. This slice is attached to objects. Solid so that they expand or shrink together, and stress occurs on the solid body, which is matched by a change in the value of the electrical resistance of the slice.

The “strain gauge” was invented by an electrical engineer named Edward E. Simmons, graduated in 1934 in Los Angeles, California, USA, when he was working at the California Institute of Technology in 1938.

“HBM”, “VISHAY” and “TML” are among the most famous companies that manufacture and develop “FOIL STRAIN GAUGE”, which is used in the manufacture of Weight instrument. A large number of companies in East Asia have entered this field, which helped them to manufacture weighing cells at very low prices that have reached the cost limit.

The “FOIL Strain Gauge” is attached according to the desired direction to measure the coefficient of expansion, contraction or curvature, and they are connected electrically together in a manner similar to the “Hotstone Strain” that we referred to in the first issue of the “World of Scales” magazine. This bridge can be formed with one number “FOIL Strain Gauge” and three Fixed rectifiers called “quarter bridge” or with two “FOIL Strain Gauge” and two fixed resistors called “Half Bridge” or with four “FOIL Strain Gauge” called “Full Bridge” and the best and most accurate type of connection is the last type “Full Bridge” where two are operated “FOIL Strain Gauge” in the direction of tension (red arrows) and two in the direction of pressure (blue arrows), which enables us to measure the smallest stress to which the metal of the body of the Weight instrument is subjected.

The “FOIL Strain Gauge” is affixed to the metal body of the weighing cells with special adhesives, and it is a type of epoxy.

The case “One Gage” and the case “Tow Gages” are used only in tensile cells, while the case “Four Gage” is used in the cell that works in both cases of tension or compression. Figures 7 to 9 show the following:

The stage after cleaning the metal surface, applying the adhesive to the metal body, and placing the “Strain Gauge” letter on the metal surface.

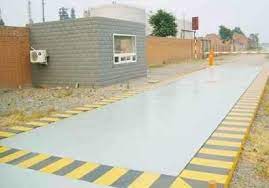

Weight instrument - Weight instrument, also called car scales, are scales used to weigh trucks. It is a truck scale on which the truck stands, and the scale is connected to a computer room that calculates and prints the weight. The goal of truck weighing is when we need to calculate a specific weight. Let's assume a truck of iron and we want to calculate the weight of the iron in this truck. The truck is mounted with iron on the scale and the weight is calculated. Then the empty truck gets on the scale. And the weight is calculated. And we find that the weight of the iron in this case is the weight of the truck with iron less than the weight of the truck without the iron.

What to look for when buying Weight instrument

Are you thinking of buying Weight instrument or upgrading the current scale? There are some simple tips that can help you feel confident in your decision and avoid buyer's remorse.

Download the free Weight instrument Buying Guide

View our free accuracy webinar

Learn about the reliability of Weight instrument

Buying Weight instrument is not an easy task. There are a lot of options to consider, as different companies provide an abundance of information. The truth is that all Weight instrument will perform in approximately the same way and effectively for the first few years after purchase. And whether you buy the cheapest scale or the most expensive one - these scales will work pretty much the same way at first.

As a smart buyer, you will look to the future of your Weight instrument. How much will total ownership cost in 20 years? Here are some things to consider as they greatly affect the true cost of a scale:

Precision

Your Weight instrument act as a cash register for your business. Doesn't it bother you to rip customers off a few bucks in the checkout area on every purchase? With an inaccurate scale, this will be the case. Don't be fooled by marketing that only offers NTAP or ILO testing certifications, these systems allow for a degree of error that will cause you to lose your product to the truckload. Ask for accuracy data, and in case those companies can't provide it to you - cross this company off your list.

reliability

As mentioned above, most Weight instrument will perform nearly as well for the first few years. However, parts start to wear out over time - and with worn and broken parts you incur costly downtime, not to mention service expenses. And every day that goes by and your scales are broken, you incur losses in your business. Make sure your list of questions when buying Weight instrument includes reliability and uptime.

Security

When purchasing a product that should last 20 years or more, warranty is a very important factor to consider. And with a warranty that offers very low insurance coverage, you'll end up incurring more repair expenses over the life of the scale than you paid for the scale in the first place. This is especially true for companies with poor reliability or a high failure rate of load cells. Even if only one or two load cells fail each year, that adds up to thousands of dollars over time.

As a knowledgeable buyer, you can have more confidence when purchasing your Weight instrument and avoid major problems in the future.

Fortunately, there is one company that excels in all of these requirements. METTLER TOLEDO Weight instrument with the POWERCELL® PDX® System give you industry-leading accuracy and reliability, and now offer an industry-leading warranty. Backed by a 10-year warranty on the POWERCELL® PDX® system, you can be confident in your truck scale purchase.

Download the free Weight instrument Buying Guide

View our free accuracy webinar

Learn about the reliability of Weight instrument

(Baskool scales)

Weight instrument are used all over the world, whether in small projects at the level of individuals or large businesses at the level of factories and governments. Weight instrument are used to determine the weight of Weight instrument, or more precisely, the goods loaded on huge trucks.

Determining the weight of the goods loaded on the trucks is considered an important matter, due to the consequent determination of the sale or purchase prices, or the determination of the permitting of trucks to pass on some roads. Therefore, the information and data that are read by scales must be accurate and do not bear any percentage. of mistakes.

It must also be taken into account when making a decision to purchase or design Weight instrument that it works on roads or open places, and therefore the validity of the scale to work in all environmental conditions and to resist all climatic influences (rain - humidity - heat - cold ... etc.) must be taken into account. )

How do Weight instrument work?

The Weight instrument calculate the weight of the empty truck without any load, then after filling the load, the scale calculates the truck + the cargo load, and by calculating the difference between the two loads, the net weight of the goods loaded on the vehicle can be calculated.

Components of Weight instrument

foundations

weight cells

Cables and connections

Weight read screen

Invoice printing device

Technical specifications for Weight instrument

Truck scale sizes

The dimensions of the Weight instrument and the size of the tiles must be chosen to suit the size of the trucks that will be dealt with in the future. Also, take into account the different sizes of trucks from one country to another.

Al-Ittihad Company for Trade and Supplies provides all sizes of Weight instrument to suit different uses, so that the length of the Weight instrument ranges from (6 to 24 meters) and the width is (3 meters).

Metal slabs and concrete slabs

The slabs of Weight instrument mean the virtual surface of the scale on which the trucks move directly.

Weight instrument with a metal deck (steel deck) are often set up in factories and workshops, and are characterized by their quick completion and ease of transportation and assembly at the site. However, slip factors must be taken into account in the case of humidity and rain.

Concrete deck Weight instrument of this type are equipped with constructions on site directly.

Weight reading screens

Digital screens are used to read the different weights, and they are also provided with special programs to print the invoice and basic data, and create a database for the weights and goods that are dealt with.

Weight instrument - Weight instrument, also called car scales, are scales used to weigh trucks. It is a truck scale on which the truck stands, and the scale is connected to a computer room that calculates and prints the weight. The goal of truck weighing is when we need to calculate a specific weight. Let's assume a truck of iron and we want to calculate the weight of the iron in this truck. The truck is mounted with iron on the scale and the weight is calculated. Then the empty truck gets on the scale. And the weight is calculated. And we find that the weight of the iron in this case is the weight of the truck with iron less than the weight of the truck without the iron.

What to look for when buying Weight instrument

Are you thinking of buying Weight instrument or upgrading the current scale? There are some simple tips that can help you feel confident in your decision and avoid buyer's remorse.

Download the free Weight instrument Buying Guide

View our free accuracy webinar

Learn about the reliability of Weight instrument

Buying Weight instrument is not an easy task. There are a lot of options to consider, as different companies provide an abundance of information. The truth is that all Weight instrument will perform in approximately the same way and effectively for the first few years after purchase. And whether you buy the cheapest scale or the most expensive one - these scales will work pretty much the same way at first.

As a smart buyer, you will look to the future of your Weight instrument. How much will total ownership cost in 20 years? Here are some things to consider as they greatly affect the true cost of a scale:

Precision

Your Weight instrument act as a cash register for your business. Doesn't it bother you to rip customers off a few bucks in the checkout area on every purchase? With an inaccurate scale, this will be the case. Don't be fooled by marketing that only offers NTAP or ILO testing certifications, these systems allow for a degree of error that will cause you to lose your product to the truckload. Ask for accuracy data, and in case those companies can't provide it to you - cross this company off your list.

reliability

As mentioned above, most Weight instrument will perform nearly as well for the first few years. However, parts start to wear out over time - and with worn and broken parts you incur costly downtime, not to mention service expenses. And every day that goes by and your scales are broken, you incur losses in your business. Make sure your list of questions when buying Weight instrument includes reliability and uptime.

Security

When purchasing a product that should last 20 years or more, warranty is a very important factor to consider. And with a warranty that offers very low insurance coverage, you'll end up incurring more repair expenses over the life of the scale than you paid for the scale in the first place. This is especially true for companies with poor reliability or a high failure rate of load cells. Even if only one or two load cells fail each year, that adds up to thousands of dollars over time.

As a knowledgeable buyer, you can have more confidence when purchasing your Weight instrument and avoid major problems in the future.

Fortunately, there is one company that excels in all of these requirements. METTLER TOLEDO Weight instrument with the POWERCELL® PDX® System give you industry-leading accuracy and reliability, and now offer an industry-leading warranty. Backed by a 10-year warranty on the POWERCELL® PDX® system, you can be confident in your truck scale purchase.

Download the free Weight instrument Buying Guide

View our free accuracy webinar

Learn about the reliability of Weight instrument

(Baskool scales)

Weight instrument are used all over the world, whether in small projects at the level of individuals or large businesses at the level of factories and governments. Weight instrument are used to determine the weight of Weight instrument, or more precisely, the goods loaded on huge trucks.

Determining the weight of the goods loaded on the trucks is considered an important matter, due to the consequent determination of the sale or purchase prices, or the determination of the permitting of trucks to pass on some roads. Therefore, the information and data that are read by scales must be accurate and do not bear any percentage. of mistakes.

It must also be taken into account when making a decision to purchase or design Weight instrument that it works on roads or open places, and therefore the validity of the scale to work in all environmental conditions and to resist all climatic influences (rain - humidity - heat - cold ... etc.) must be taken into account. )

How do Weight instrument work?

The Weight instrument calculate the weight of the empty truck without any load, then after filling the load, the scale calculates the truck + the cargo load, and by calculating the difference between the two loads, the net weight of the goods loaded on the vehicle can be calculated.

Components of Weight instrument

foundations

weight cells

Cables and connections

Weight read screen

Invoice printing device

Technical specifications for Weight instrument

Truck scale sizes

The dimensions of the Weight instrument and the size of the tiles must be chosen to suit the size of the trucks that will be dealt with in the future. Also, take into account the different sizes of trucks from one country to another.

Al-Ittihad Company for Trade and Supplies provides all sizes of Weight instrument to suit different uses, so that the length of the Weight instrument ranges from (6 to 24 meters) and the width is (3 meters).

Metal slabs and concrete slabs

The slabs of Weight instrument mean the virtual surface of the scale on which the trucks move directly.

Weight instrument with a metal deck (steel deck) are often set up in factories and workshops, and are characterized by their quick completion and ease of transportation and assembly at the site. However, slip factors must be taken into account in the case of humidity and rain.

Concrete deck Weight instrument of this type are equipped with constructions on site directly.

Weight reading screens

Digital screens are used to read the different weights, and they are also provided with special programs to print the invoice and basic data, and create a database for the weights and goods that are dealt with.

Weight instrument - Weight instrument, also called car scales, are scales used to weigh trucks. It is a truck scale on which the truck stands, and the scale is connected to a computer room that calculates and prints the weight. The goal of truck weighing is when we need to calculate a specific weight. Let's assume a truck of iron and we want to calculate the weight of the iron in this truck. The truck is mounted with iron on the scale and the weight is calculated. Then the empty truck gets on the scale. And the weight is calculated. And we find that the weight of the iron in this case is the weight of the truck with iron less than the weight of the truck without the iron.

What to look for when buying Weight instrument

Are you thinking of buying Weight instrument or upgrading the current scale? There are some simple tips that can help you feel confident in your decision and avoid buyer's remorse.

Download the free Weight instrument Buying Guide

View our free accuracy webinar

Learn about the reliability of Weight instrument

Buying Weight instrument is not an easy task. There are a lot of options to consider, as different companies provide an abundance of information. The truth is that all Weight instrument will perform in approximately the same way and effectively for the first few years after purchase. And whether you buy the cheapest scale or the most expensive one - these scales will work pretty much the same way at first.

As a smart buyer, you will look to the future of your Weight instrument. How much will total ownership cost in 20 years? Here are some things to consider as they greatly affect the true cost of a scale:

Precision

Your Weight instrument act as a cash register for your business. Doesn't it bother you to rip customers off a few bucks in the checkout area on every purchase? With an inaccurate scale, this will be the case. Don't be fooled by marketing that only offers NTAP or ILO testing certifications, these systems allow for a degree of error that will cause you to lose your product to the truckload. Ask for accuracy data, and in case those companies can't provide it to you - cross this company off your list.

reliability

As mentioned above, most Weight instrument will perform nearly as well for the first few years. However, parts start to wear out over time - and with worn and broken parts you incur costly downtime, not to mention service expenses. And every day that goes by and your scales are broken, you incur losses in your business. Make sure your list of questions when buying Weight instrument includes reliability and uptime.

Security

When purchasing a product that should last 20 years or more, warranty is a very important factor to consider. And with a warranty that offers very low insurance coverage, you'll end up incurring more repair expenses over the life of the scale than you paid for the scale in the first place. This is especially true for companies with poor reliability or a high failure rate of load cells. Even if only one or two load cells fail each year, that adds up to thousands of dollars over time.

As a knowledgeable buyer, you can have more confidence when purchasing your Weight instrument and avoid major problems in the future.

Fortunately, there is one company that excels in all of these requirements. METTLER TOLEDO Weight instrument with the POWERCELL® PDX® System give you industry-leading accuracy and reliability, and now offer an industry-leading warranty. Backed by a 10-year warranty on the POWERCELL® PDX® system, you can be confident in your truck scale purchase.

Download the free Weight instrument Buying Guide

View our free accuracy webinar

Learn about the reliability of Weight instrument

(Baskool scales)

Weight instrument are used all over the world, whether in small projects at the level of individuals or large businesses at the level of factories and governments. Weight instrument are used to determine the weight of Weight instrument, or more precisely, the goods loaded on huge trucks.

Determining the weight of the goods loaded on the trucks is considered an important matter, due to the consequent determination of the sale or purchase prices, or the determination of the permitting of trucks to pass on some roads. Therefore, the information and data that are read by scales must be accurate and do not bear any percentage. of mistakes.

It must also be taken into account when making a decision to purchase or design Weight instrument that it works on roads or open places, and therefore the validity of the scale to work in all environmental conditions and to resist all climatic influences (rain - humidity - heat - cold ... etc.) must be taken into account. )

How do Weight instrument work?

The Weight instrument calculate the weight of the empty truck without any load, then after filling the load, the scale calculates the truck + the cargo load, and by calculating the difference between the two loads, the net weight of the goods loaded on the vehicle can be calculated.

Components of Weight instrument

foundations

weight cells

Cables and connections

Weight read screen

Invoice printing device

Technical specifications for Weight instrument

Truck scale sizes

The dimensions of the Weight instrument and the size of the tiles must be chosen to suit the size of the trucks that will be dealt with in the future. Also, take into account the different sizes of trucks from one country to another.

Al-Ittihad Company for Trade and Supplies provides all sizes of Weight instrument to suit different uses, so that the length of the Weight instrument ranges from (6 to 24 meters) and the width is (3 meters).

Metal slabs and concrete slabs

The slabs of Weight instrument mean the virtual surface of the scale on which the trucks move directly.

Weight instrument with a metal deck (steel deck) are often set up in factories and workshops, and are characterized by their quick completion and ease of transportation and assembly at the site. However, slip factors must be taken into account in the case of humidity and rain.

Concrete deck Weight instrument of this type are equipped with constructions on site directly.

Weight reading screens

Digital screens are used to read the different weights, and they are also provided with special programs to print the invoice and basic data, and create a database for the weights and goods that are dealt with.

Weight instrument - Weight instrument, also called car scales, are scales used to weigh trucks. It is a truck scale on which the truck stands, and the scale is connected to a computer room that calculates and prints the weight. The goal of truck weighing is when we need to calculate a specific weight. Let's assume a truck of iron and we want to calculate the weight of the iron in this truck. The truck is mounted with iron on the scale and the weight is calculated. Then the empty truck gets on the scale. And the weight is calculated. And we find that the weight of the iron in this case is the weight of the truck with iron less than the weight of the truck without the iron.

What to look for when buying Weight instrument

Are you thinking of buying Weight instrument or upgrading the current scale? There are some simple tips that can help you feel confident in your decision and avoid buyer's remorse.

Download the free Weight instrument Buying Guide

View our free accuracy webinar

Learn about the reliability of Weight instrument

Buying Weight instrument is not an easy task. There are a lot of options to consider, as different companies provide an abundance of information. The truth is that all Weight instrument will perform in approximately the same way and effectively for the first few years after purchase. And whether you buy the cheapest scale or the most expensive one - these scales will work pretty much the same way at first.

As a smart buyer, you will look to the future of your Weight instrument. How much will total ownership cost in 20 years? Here are some things to consider as they greatly affect the true cost of a scale:

Precision

Your Weight instrument act as a cash register for your business. Doesn't it bother you to rip customers off a few bucks in the checkout area on every purchase? With an inaccurate scale, this will be the case. Don't be fooled by marketing that only offers NTAP or ILO testing certifications, these systems allow for a degree of error that will cause you to lose your product to the truckload. Ask for accuracy data, and in case those companies can't provide it to you - cross this company off your list.

reliability

As mentioned above, most Weight instrument will perform nearly as well for the first few years. However, parts start to wear out over time - and with worn and broken parts you incur costly downtime, not to mention service expenses. And every day that goes by and your scales are broken, you incur losses in your business. Make sure your list of questions when buying Weight instrument includes reliability and uptime.

Security

When purchasing a product that should last 20 years or more, warranty is a very important factor to consider. And with a warranty that offers very low insurance coverage, you'll end up incurring more repair expenses over the life of the scale than you paid for the scale in the first place. This is especially true for companies with poor reliability or a high failure rate of load cells. Even if only one or two load cells fail each year, that adds up to thousands of dollars over time.

As a knowledgeable buyer, you can have more confidence when purchasing your Weight instrument and avoid major problems in the future.

Fortunately, there is one company that excels in all of these requirements. METTLER TOLEDO Weight instrument with the POWERCELL® PDX® System give you industry-leading accuracy and reliability, and now offer an industry-leading warranty. Backed by a 10-year warranty on the POWERCELL® PDX® system, you can be confident in your truck scale purchase.

Download the free Weight instrument Buying Guide

View our free accuracy webinar

Learn about the reliability of Weight instrument

(Baskool scales)

Weight instrument are used all over the world, whether in small projects at the level of individuals or large businesses at the level of factories and governments. Weight instrument are used to determine the weight of Weight instrument, or more precisely, the goods loaded on huge trucks.

Determining the weight of the goods loaded on the trucks is considered an important matter, due to the consequent determination of the sale or purchase prices, or the determination of the permitting of trucks to pass on some roads. Therefore, the information and data that are read by scales must be accurate and do not bear any percentage. of mistakes.

It must also be taken into account when making a decision to purchase or design Weight instrument that it works on roads or open places, and therefore the validity of the scale to work in all environmental conditions and to resist all climatic influences (rain - humidity - heat - cold ... etc.) must be taken into account. )

How do Weight instrument work?

The Weight instrument calculate the weight of the empty truck without any load, then after filling the load, the scale calculates the truck + the cargo load, and by calculating the difference between the two loads, the net weight of the goods loaded on the vehicle can be calculated.

Components of Weight instrument

foundations

weight cells

Cables and connections

Weight read screen

Invoice printing device

Technical specifications for Weight instrument

Truck scale sizes

The dimensions of the Weight instrument and the size of the tiles must be chosen to suit the size of the trucks that will be dealt with in the future. Also, take into account the different sizes of trucks from one country to another.

Al-Ittihad Company for Trade and Supplies provides all sizes of Weight instrument to suit different uses, so that the length of the Weight instrument ranges from (6 to 24 meters) and the width is (3 meters).

Metal slabs and concrete slabs

The slabs of Weight instrument mean the virtual surface of the scale on which the trucks move directly.

Weight instrument with a metal deck (steel deck) are often set up in factories and workshops, and are characterized by their quick completion and ease of transportation and assembly at the site. However, slip factors must be taken into account in the case of humidity and rain.

Concrete deck Weight instrument of this type are equipped with constructions on site directly.

Weight reading screens

Digital screens are used to read the different weights, and they are also provided with special programs to print the invoice and basic data, and create a database for the weights and goods that are dealt with.

Weight instrument - Weight instrument, also called car scales, are scales used to weigh trucks. It is a truck scale on which the truck stands, and the scale is connected to a computer room that calculates and prints the weight. The goal of truck weighing is when we need to calculate a specific weight. Let's assume a truck of iron and we want to calculate the weight of the iron in this truck. The truck is mounted with iron on the scale and the weight is calculated. Then the empty truck gets on the scale. And the weight is calculated. And we find that the weight of the iron in this case is the weight of the truck with iron less than the weight of the truck without the iron.

What to look for when buying Weight instrument

Are you thinking of buying Weight instrument or upgrading the current scale? There are some simple tips that can help you feel confident in your decision and avoid buyer's remorse.

Download the free Weight instrument Buying Guide

View our free accuracy webinar

Learn about the reliability of Weight instrument

Buying Weight instrument is not an easy task. There are a lot of options to consider, as different companies provide an abundance of information. The truth is that all Weight instrument will perform in approximately the same way and effectively for the first few years after purchase. And whether you buy the cheapest scale or the most expensive one - these scales will work pretty much the same way at first.

As a smart buyer, you will look to the future of your Weight instrument. How much will total ownership cost in 20 years? Here are some things to consider as they greatly affect the true cost of a scale:

Precision

Your Weight instrument act as a cash register for your business. Doesn't it bother you to rip customers off a few bucks in the checkout area on every purchase? With an inaccurate scale, this will be the case. Don't be fooled by marketing that only offers NTAP or ILO testing certifications, these systems allow for a degree of error that will cause you to lose your product to the truckload. Ask for accuracy data, and in case those companies can't provide it to you - cross this company off your list.

reliability

As mentioned above, most Weight instrument will perform nearly as well for the first few years. However, parts start to wear out over time - and with worn and broken parts you incur costly downtime, not to mention service expenses. And every day that goes by and your scales are broken, you incur losses in your business. Make sure your list of questions when buying Weight instrument includes reliability and uptime.

Security

When purchasing a product that should last 20 years or more, warranty is a very important factor to consider. And with a warranty that offers very low insurance coverage, you'll end up incurring more repair expenses over the life of the scale than you paid for the scale in the first place. This is especially true for companies with poor reliability or a high failure rate of load cells. Even if only one or two load cells fail each year, that adds up to thousands of dollars over time.

As a knowledgeable buyer, you can have more confidence when purchasing your Weight instrument and avoid major problems in the future.

Fortunately, there is one company that excels in all of these requirements. METTLER TOLEDO Weight instrument with the POWERCELL® PDX® System give you industry-leading accuracy and reliability, and now offer an industry-leading warranty. Backed by a 10-year warranty on the POWERCELL® PDX® system, you can be confident in your truck scale purchase.

Download the free Weight instrument Buying Guide

View our free accuracy webinar

Learn about the reliability of Weight instrument

(Baskool scales)

Weight instrument are used all over the world, whether in small projects at the level of individuals or large businesses at the level of factories and governments. Weight instrument are used to determine the weight of Weight instrument, or more precisely, the goods loaded on huge trucks.

Determining the weight of the goods loaded on the trucks is considered an important matter, due to the consequent determination of the sale or purchase prices, or the determination of the permitting of trucks to pass on some roads. Therefore, the information and data that are read by scales must be accurate and do not bear any percentage. of mistakes.

It must also be taken into account when making a decision to purchase or design Weight instrument that it works on roads or open places, and therefore the validity of the scale to work in all environmental conditions and to resist all climatic influences (rain - humidity - heat - cold ... etc.) must be taken into account. )

How do Weight instrument work?

The Weight instrument calculate the weight of the empty truck without any load, then after filling the load, the scale calculates the truck + the cargo load, and by calculating the difference between the two loads, the net weight of the goods loaded on the vehicle can be calculated.

Components of Weight instrument

foundations

weight cells

Cables and connections

Weight read screen

Invoice printing device

Technical specifications for Weight instrument

Truck scale sizes

The dimensions of the Weight instrument and the size of the tiles must be chosen to suit the size of the trucks that will be dealt with in the future. Also, take into account the different sizes of trucks from one country to another.

Al-Ittihad Company for Trade and Supplies provides all sizes of Weight instrument to suit different uses, so that the length of the Weight instrument ranges from (6 to 24 meters) and the width is (3 meters).

Metal slabs and concrete slabs

The slabs of Weight instrument mean the virtual surface of the scale on which the trucks move directly.

Weight instrument with a metal deck (steel deck) are often set up in factories and workshops, and are characterized by their quick completion and ease of transportation and assembly at the site. However, slip factors must be taken into account in the case of humidity and rain.

Concrete deck Weight instrument of this type are equipped with constructions on site directly.

Weight reading screens

Digital screens are used to read the different weights, and they are also provided with special programs to print the invoice and basic data, and create a database for the weights and goods that are dealt with.

Weight instrument - Weight instrument, also called car scales, are scales used to weigh trucks. It is a truck scale on which the truck stands, and the scale is connected to a computer room that calculates and prints the weight. The goal of truck weighing is when we need to calculate a specific weight. Let's assume a truck of iron and we want to calculate the weight of the iron in this truck. The truck is mounted with iron on the scale and the weight is calculated. Then the empty truck gets on the scale. And the weight is calculated. And we find that the weight of the iron in this case is the weight of the truck with iron less than the weight of the truck without the iron.

What to look for when buying Weight instrument

Are you thinking of buying Weight instrument or upgrading the current scale? There are some simple tips that can help you feel confident in your decision and avoid buyer's remorse.

Download the free Weight instrument Buying Guide

View our free accuracy webinar

Learn about the reliability of Weight instrument

Buying Weight instrument is not an easy task. There are a lot of options to consider, as different companies provide an abundance of information. The truth is that all Weight instrument will perform in approximately the same way and effectively for the first few years after purchase. And whether you buy the cheapest scale or the most expensive one - these scales will work pretty much the same way at first.

As a smart buyer, you will look to the future of your Weight instrument. How much will total ownership cost in 20 years? Here are some things to consider as they greatly affect the true cost of a scale:

Precision

Your Weight instrument act as a cash register for your business. Doesn't it bother you to rip customers off a few bucks in the checkout area on every purchase? With an inaccurate scale, this will be the case. Don't be fooled by marketing that only offers NTAP or ILO testing certifications, these systems allow for a degree of error that will cause you to lose your product to the truckload. Ask for accuracy data, and in case those companies can't provide it to you - cross this company off your list.

reliability

As mentioned above, most Weight instrument will perform nearly as well for the first few years. However, parts start to wear out over time - and with worn and broken parts you incur costly downtime, not to mention service expenses. And every day that goes by and your scales are broken, you incur losses in your business. Make sure your list of questions when buying Weight instrument includes reliability and uptime.

Security

When purchasing a product that should last 20 years or more, warranty is a very important factor to consider. And with a warranty that offers very low insurance coverage, you'll end up incurring more repair expenses over the life of the scale than you paid for the scale in the first place. This is especially true for companies with poor reliability or a high failure rate of load cells. Even if only one or two load cells fail each year, that adds up to thousands of dollars over time.

As a knowledgeable buyer, you can have more confidence when purchasing your Weight instrument and avoid major problems in the future.

Fortunately, there is one company that excels in all of these requirements. METTLER TOLEDO Weight instrument with the POWERCELL® PDX® System give you industry-leading accuracy and reliability, and now offer an industry-leading warranty. Backed by a 10-year warranty on the POWERCELL® PDX® system, you can be confident in your truck scale purchase.

Download the free Weight instrument Buying Guide

View our free accuracy webinar

Learn about the reliability of Weight instrument

(Baskool scales)

Weight instrument are used all over the world, whether in small projects at the level of individuals or large businesses at the level of factories and governments. Weight instrument are used to determine the weight of Weight instrument, or more precisely, the goods loaded on huge trucks.

Determining the weight of the goods loaded on the trucks is considered an important matter, due to the consequent determination of the sale or purchase prices, or the determination of the permitting of trucks to pass on some roads. Therefore, the information and data that are read by scales must be accurate and do not bear any percentage. of mistakes.

It must also be taken into account when making a decision to purchase or design Weight instrument that it works on roads or open places, and therefore the validity of the scale to work in all environmental conditions and to resist all climatic influences (rain - humidity - heat - cold ... etc.) must be taken into account. )

How do Weight instrument work?

The Weight instrument calculate the weight of the empty truck without any load, then after filling the load, the scale calculates the truck + the cargo load, and by calculating the difference between the two loads, the net weight of the goods loaded on the vehicle can be calculated.

Components of Weight instrument

foundations

weight cells

Cables and connections

Weight read screen

Invoice printing device

Technical specifications for Weight instrument

Truck scale sizes

The dimensions of the Weight instrument and the size of the tiles must be chosen to suit the size of the trucks that will be dealt with in the future. Also, take into account the different sizes of trucks from one country to another.

Al-Ittihad Company for Trade and Supplies provides all sizes of Weight instrument to suit different uses, so that the length of the Weight instrument ranges from (6 to 24 meters) and the width is (3 meters).

Metal slabs and concrete slabs

The slabs of Weight instrument mean the virtual surface of the scale on which the trucks move directly.

Weight instrument with a metal deck (steel deck) are often set up in factories and workshops, and are characterized by their quick completion and ease of transportation and assembly at the site. However, slip factors must be taken into account in the case of humidity and rain.

Concrete deck Weight instrument of this type are equipped with constructions on site directly.

Weight reading screens

Digital screens are used to read the different weights, and they are also provided with special programs to print the invoice and basic data, and create a database for the weights and goods that are dealt with.

Weight instrument - Weight instrument, also called car scales, are scales used to weigh trucks. It is a truck scale on which the truck stands, and the scale is connected to a computer room that calculates and prints the weight. The goal of truck weighing is when we need to calculate a specific weight. Let's assume a truck of iron and we want to calculate the weight of the iron in this truck. The truck is mounted with iron on the scale and the weight is calculated. Then the empty truck gets on the scale. And the weight is calculated. And we find that the weight of the iron in this case is the weight of the truck with iron less than the weight of the truck without the iron.

What to look for when buying Weight instrument

Are you thinking of buying Weight instrument or upgrading the current scale? There are some simple tips that can help you feel confident in your decision and avoid buyer's remorse.

Download the free Weight instrument Buying Guide

View our free accuracy webinar

Learn about the reliability of Weight instrument

Buying Weight instrument is not an easy task. There are a lot of options to consider, as different companies provide an abundance of information. The truth is that all Weight instrument will perform in approximately the same way and effectively for the first few years after purchase. And whether you buy the cheapest scale or the most expensive one - these scales will work pretty much the same way at first.

As a smart buyer, you will look to the future of your Weight instrument. How much will total ownership cost in 20 years? Here are some things to consider as they greatly affect the true cost of a scale:

Precision

Your Weight instrument act as a cash register for your business. Doesn't it bother you to rip customers off a few bucks in the checkout area on every purchase? With an inaccurate scale, this will be the case. Don't be fooled by marketing that only offers NTAP or ILO testing certifications, these systems allow for a degree of error that will cause you to lose your product to the truckload. Ask for accuracy data, and in case those companies can't provide it to you - cross this company off your list.

reliability

As mentioned above, most Weight instrument will perform nearly as well for the first few years. However, parts start to wear out over time - and with worn and broken parts you incur costly downtime, not to mention service expenses. And every day that goes by and your scales are broken, you incur losses in your business. Make sure your list of questions when buying Weight instrument includes reliability and uptime.

Security

When purchasing a product that should last 20 years or more, warranty is a very important factor to consider. And with a warranty that offers very low insurance coverage, you'll end up incurring more repair expenses over the life of the scale than you paid for the scale in the first place. This is especially true for companies with poor reliability or a high failure rate of load cells. Even if only one or two load cells fail each year, that adds up to thousands of dollars over time.

As a knowledgeable buyer, you can have more confidence when purchasing your Weight instrument and avoid major problems in the future.

Fortunately, there is one company that excels in all of these requirements. METTLER TOLEDO Weight instrument with the POWERCELL® PDX® System give you industry-leading accuracy and reliability, and now offer an industry-leading warranty. Backed by a 10-year warranty on the POWERCELL® PDX® system, you can be confident in your truck scale purchase.

Download the free Weight instrument Buying Guide

View our free accuracy webinar

Learn about the reliability of Weight instrument

(Baskool scales)

Weight instrument are used all over the world, whether in small projects at the level of individuals or large businesses at the level of factories and governments. Weight instrument are used to determine the weight of Weight instrument, or more precisely, the goods loaded on huge trucks.

Determining the weight of the goods loaded on the trucks is considered an important matter, due to the consequent determination of the sale or purchase prices, or the determination of the permitting of trucks to pass on some roads. Therefore, the information and data that are read by scales must be accurate and do not bear any percentage. of mistakes.

It must also be taken into account when making a decision to purchase or design Weight instrument that it works on roads or open places, and therefore the validity of the scale to work in all environmental conditions and to resist all climatic influences (rain - humidity - heat - cold ... etc.) must be taken into account. )

How do Weight instrument work?

The Weight instrument calculate the weight of the empty truck without any load, then after filling the load, the scale calculates the truck + the cargo load, and by calculating the difference between the two loads, the net weight of the goods loaded on the vehicle can be calculated.

Components of Weight instrument

foundations

weight cells

Cables and connections

Weight read screen

Invoice printing device

Technical specifications for Weight instrument

Truck scale sizes

The dimensions of the Weight instrument and the size of the tiles must be chosen to suit the size of the trucks that will be dealt with in the future. Also, take into account the different sizes of trucks from one country to another.

Al-Ittihad Company for Trade and Supplies provides all sizes of Weight instrument to suit different uses, so that the length of the Weight instrument ranges from (6 to 24 meters) and the width is (3 meters).

Metal slabs and concrete slabs

The slabs of Weight instrument mean the virtual surface of the scale on which the trucks move directly.

Weight instrument with a metal deck (steel deck) are often set up in factories and workshops, and are characterized by their quick completion and ease of transportation and assembly at the site. However, slip factors must be taken into account in the case of humidity and rain.

Concrete deck Weight instrument of this type are equipped with constructions on site directly.

Weight reading screens

Digital screens are used to read the different weights, and they are also provided with special programs to print the invoice and basic data, and create a database for the weights and goods that are dealt with.

Weight instrument - Weight instrument, also called car scales, are scales used to weigh trucks. It is a truck scale on which the truck stands, and the scale is connected to a computer room that calculates and prints the weight. The goal of truck weighing is when we need to calculate a specific weight. Let's assume a truck of iron and we want to calculate the weight of the iron in this truck. The truck is mounted with iron on the scale and the weight is calculated. Then the empty truck gets on the scale. And the weight is calculated. And we find that the weight of the iron in this case is the weight of the truck with iron less than the weight of the truck without the iron.

What to look for when buying Weight instrument

Are you thinking of buying Weight instrument or upgrading the current scale? There are some simple tips that can help you feel confident in your decision and avoid buyer's remorse.

Download the free Weight instrument Buying Guide

View our free accuracy webinar

Learn about the reliability of Weight instrument

Buying Weight instrument is not an easy task. There are a lot of options to consider, as different companies provide an abundance of information. The truth is that all Weight instrument will perform in approximately the same way and effectively for the first few years after purchase. And whether you buy the cheapest scale or the most expensive one - these scales will work pretty much the same way at first.

As a smart buyer, you will look to the future of your Weight instrument. How much will total ownership cost in 20 years? Here are some things to consider as they greatly affect the true cost of a scale:

Precision

Your Weight instrument act as a cash register for your business. Doesn't it bother you to rip customers off a few bucks in the checkout area on every purchase? With an inaccurate scale, this will be the case. Don't be fooled by marketing that only offers NTAP or ILO testing certifications, these systems allow for a degree of error that will cause you to lose your product to the truckload. Ask for accuracy data, and in case those companies can't provide it to you - cross this company off your list.

reliability

As mentioned above, most Weight instrument will perform nearly as well for the first few years. However, parts start to wear out over time - and with worn and broken parts you incur costly downtime, not to mention service expenses. And every day that goes by and your scales are broken, you incur losses in your business. Make sure your list of questions when buying Weight instrument includes reliability and uptime.

Security

When purchasing a product that should last 20 years or more, warranty is a very important factor to consider. And with a warranty that offers very low insurance coverage, you'll end up incurring more repair expenses over the life of the scale than you paid for the scale in the first place. This is especially true for companies with poor reliability or a high failure rate of load cells. Even if only one or two load cells fail each year, that adds up to thousands of dollars over time.

As a knowledgeable buyer, you can have more confidence when purchasing your Weight instrument and avoid major problems in the future.

Fortunately, there is one company that excels in all of these requirements. METTLER TOLEDO Weight instrument with the POWERCELL® PDX® System give you industry-leading accuracy and reliability, and now offer an industry-leading warranty. Backed by a 10-year warranty on the POWERCELL® PDX® system, you can be confident in your truck scale purchase.

Download the free Weight instrument Buying Guide

View our free accuracy webinar

Learn about the reliability of Weight instrument

(Baskool scales)

Weight instrument are used all over the world, whether in small projects at the level of individuals or large businesses at the level of factories and governments. Weight instrument are used to determine the weight of Weight instrument, or more precisely, the goods loaded on huge trucks.

Determining the weight of the goods loaded on the trucks is considered an important matter, due to the consequent determination of the sale or purchase prices, or the determination of the permitting of trucks to pass on some roads. Therefore, the information and data that are read by scales must be accurate and do not bear any percentage. of mistakes.

It must also be taken into account when making a decision to purchase or design Weight instrument that it works on roads or open places, and therefore the validity of the scale to work in all environmental conditions and to resist all climatic influences (rain - humidity - heat - cold ... etc.) must be taken into account. )

How do Weight instrument work?

The Weight instrument calculate the weight of the empty truck without any load, then after filling the load, the scale calculates the truck + the cargo load, and by calculating the difference between the two loads, the net weight of the goods loaded on the vehicle can be calculated.

Components of Weight instrument

foundations

weight cells

Cables and connections

Weight read screen

Invoice printing device

Technical specifications for Weight instrument

Truck scale sizes

The dimensions of the Weight instrument and the size of the tiles must be chosen to suit the size of the trucks that will be dealt with in the future. Also, take into account the different sizes of trucks from one country to another.

Al-Ittihad Company for Trade and Supplies provides all sizes of Weight instrument to suit different uses, so that the length of the Weight instrument ranges from (6 to 24 meters) and the width is (3 meters).

Metal slabs and concrete slabs

The slabs of Weight instrument mean the virtual surface of the scale on which the trucks move directly.

Weight instrument with a metal deck (steel deck) are often set up in factories and workshops, and are characterized by their quick completion and ease of transportation and assembly at the site. However, slip factors must be taken into account in the case of humidity and rain.

Concrete deck Weight instrument of this type are equipped with constructions on site directly.

Weight reading screens

Digital screens are used to read the different weights, and they are also provided with special programs to print the invoice and basic data, and create a database for the weights and goods that are dealt with.

Weight instrument - Weight instrument, also called car scales, are scales used to weigh trucks. It is a truck scale on which the truck stands, and the scale is connected to a computer room that calculates and prints the weight. The goal of truck weighing is when we need to calculate a specific weight. Let's assume a truck of iron and we want to calculate the weight of the iron in this truck. The truck is mounted with iron on the scale and the weight is calculated. Then the empty truck gets on the scale. And the weight is calculated. And we find that the weight of the iron in this case is the weight of the truck with iron less than the weight of the truck without the iron.

What to look for when buying Weight instrument

Are you thinking of buying Weight instrument or upgrading the current scale? There are some simple tips that can help you feel confident in your decision and avoid buyer's remorse.

Download the free Weight instrument Buying Guide

View our free accuracy webinar

Learn about the reliability of Weight instrument

Buying Weight instrument is not an easy task. There are a lot of options to consider, as different companies provide an abundance of information. The truth is that all Weight instrument will perform in approximately the same way and effectively for the first few years after purchase. And whether you buy the cheapest scale or the most expensive one - these scales will work pretty much the same way at first.

As a smart buyer, you will look to the future of your Weight instrument. How much will total ownership cost in 20 years? Here are some things to consider as they greatly affect the true cost of a scale:

Precision

Your Weight instrument act as a cash register for your business. Doesn't it bother you to rip customers off a few bucks in the checkout area on every purchase? With an inaccurate scale, this will be the case. Don't be fooled by marketing that only offers NTAP or ILO testing certifications, these systems allow for a degree of error that will cause you to lose your product to the truckload. Ask for accuracy data, and in case those companies can't provide it to you - cross this company off your list.

reliability

As mentioned above, most Weight instrument will perform nearly as well for the first few years. However, parts start to wear out over time - and with worn and broken parts you incur costly downtime, not to mention service expenses. And every day that goes by and your scales are broken, you incur losses in your business. Make sure your list of questions when buying Weight instrument includes reliability and uptime.

Security

When purchasing a product that should last 20 years or more, warranty is a very important factor to consider. And with a warranty that offers very low insurance coverage, you'll end up incurring more repair expenses over the life of the scale than you paid for the scale in the first place. This is especially true for companies with poor reliability or a high failure rate of load cells. Even if only one or two load cells fail each year, that adds up to thousands of dollars over time.

As a knowledgeable buyer, you can have more confidence when purchasing your Weight instrument and avoid major problems in the future.

Fortunately, there is one company that excels in all of these requirements. METTLER TOLEDO Weight instrument with the POWERCELL® PDX® System give you industry-leading accuracy and reliability, and now offer an industry-leading warranty. Backed by a 10-year warranty on the POWERCELL® PDX® system, you can be confident in your truck scale purchase.

Download the free Weight instrument Buying Guide

View our free accuracy webinar

Learn about the reliability of Weight instrument

(Baskool scales)

Weight instrument are used all over the world, whether in small projects at the level of individuals or large businesses at the level of factories and governments. Weight instrument are used to determine the weight of Weight instrument, or more precisely, the goods loaded on huge trucks.

Determining the weight of the goods loaded on the trucks is considered an important matter, due to the consequent determination of the sale or purchase prices, or the determination of the permitting of trucks to pass on some roads. Therefore, the information and data that are read by scales must be accurate and do not bear any percentage. of mistakes.

It must also be taken into account when making a decision to purchase or design Weight instrument that it works on roads or open places, and therefore the validity of the scale to work in all environmental conditions and to resist all climatic influences (rain - humidity - heat - cold ... etc.) must be taken into account. )

How do Weight instrument work?

The Weight instrument calculate the weight of the empty truck without any load, then after filling the load, the scale calculates the truck + the cargo load, and by calculating the difference between the two loads, the net weight of the goods loaded on the vehicle can be calculated.

Components of Weight instrument

foundations

weight cells

Cables and connections

Weight read screen

Invoice printing device

Technical specifications for Weight instrument

Truck scale sizes

The dimensions of the Weight instrument and the size of the tiles must be chosen to suit the size of the trucks that will be dealt with in the future. Also, take into account the different sizes of trucks from one country to another.

Al-Ittihad Company for Trade and Supplies provides all sizes of Weight instrument to suit different uses, so that the length of the Weight instrument ranges from (6 to 24 meters) and the width is (3 meters).

Metal slabs and concrete slabs

The slabs of Weight instrument mean the virtual surface of the scale on which the trucks move directly.

Weight instrument with a metal deck (steel deck) are often set up in factories and workshops, and are characterized by their quick completion and ease of transportation and assembly at the site. However, slip factors must be taken into account in the case of humidity and rain.

Concrete deck Weight instrument of this type are equipped with constructions on site directly.

Weight reading screens

Digital screens are used to read the different weights, and they are also provided with special programs to print the invoice and basic data, and create a database for the weights and goods that are dealt with.

Weight instrument - Weight instrument, also called car scales, are scales used to weigh trucks. It is a truck scale on which the truck stands, and the scale is connected to a computer room that calculates and prints the weight. The goal of truck weighing is when we need to calculate a specific weight. Let's assume a truck of iron and we want to calculate the weight of the iron in this truck. The truck is mounted with iron on the scale and the weight is calculated. Then the empty truck gets on the scale. And the weight is calculated. And we find that the weight of the iron in this case is the weight of the truck with iron less than the weight of the truck without the iron.

What to look for when buying Weight instrument

Are you thinking of buying Weight instrument or upgrading the current scale? There are some simple tips that can help you feel confident in your decision and avoid buyer's remorse.

Download the free Weight instrument Buying Guide

View our free accuracy webinar

Learn about the reliability of Weight instrument

Buying Weight instrument is not an easy task. There are a lot of options to consider, as different companies provide an abundance of information. The truth is that all Weight instrument will perform in approximately the same way and effectively for the first few years after purchase. And whether you buy the cheapest scale or the most expensive one - these scales will work pretty much the same way at first.

As a smart buyer, you will look to the future of your Weight instrument. How much will total ownership cost in 20 years? Here are some things to consider as they greatly affect the true cost of a scale:

Precision

Your Weight instrument act as a cash register for your business. Doesn't it bother you to rip customers off a few bucks in the checkout area on every purchase? With an inaccurate scale, this will be the case. Don't be fooled by marketing that only offers NTAP or ILO testing certifications, these systems allow for a degree of error that will cause you to lose your product to the truckload. Ask for accuracy data, and in case those companies can't provide it to you - cross this company off your list.

reliability

As mentioned above, most Weight instrument will perform nearly as well for the first few years. However, parts start to wear out over time - and with worn and broken parts you incur costly downtime, not to mention service expenses. And every day that goes by and your scales are broken, you incur losses in your business. Make sure your list of questions when buying Weight instrument includes reliability and uptime.

Security

When purchasing a product that should last 20 years or more, warranty is a very important factor to consider. And with a warranty that offers very low insurance coverage, you'll end up incurring more repair expenses over the life of the scale than you paid for the scale in the first place. This is especially true for companies with poor reliability or a high failure rate of load cells. Even if only one or two load cells fail each year, that adds up to thousands of dollars over time.

As a knowledgeable buyer, you can have more confidence when purchasing your Weight instrument and avoid major problems in the future.

Fortunately, there is one company that excels in all of these requirements. METTLER TOLEDO Weight instrument with the POWERCELL® PDX® System give you industry-leading accuracy and reliability, and now offer an industry-leading warranty. Backed by a 10-year warranty on the POWERCELL® PDX® system, you can be confident in your truck scale purchase.

Download the free Weight instrument Buying Guide

View our free accuracy webinar

Learn about the reliability of Weight instrument

(Baskool scales)

Weight instrument are used all over the world, whether in small projects at the level of individuals or large businesses at the level of factories and governments. Weight instrument are used to determine the weight of Weight instrument, or more precisely, the goods loaded on huge trucks.

Determining the weight of the goods loaded on the trucks is considered an important matter, due to the consequent determination of the sale or purchase prices, or the determination of the permitting of trucks to pass on some roads. Therefore, the information and data that are read by scales must be accurate and do not bear any percentage. of mistakes.

It must also be taken into account when making a decision to purchase or design Weight instrument that it works on roads or open places, and therefore the validity of the scale to work in all environmental conditions and to resist all climatic influences (rain - humidity - heat - cold ... etc.) must be taken into account. )

How do Weight instrument work?

The Weight instrument calculate the weight of the empty truck without any load, then after filling the load, the scale calculates the truck + the cargo load, and by calculating the difference between the two loads, the net weight of the goods loaded on the vehicle can be calculated.

Components of Weight instrument

foundations

weight cells

Cables and connections

Weight read screen

Invoice printing device

Technical specifications for Weight instrument

Truck scale sizes

The dimensions of the Weight instrument and the size of the tiles must be chosen to suit the size of the trucks that will be dealt with in the future. Also, take into account the different sizes of trucks from one country to another.

Al-Ittihad Company for Trade and Supplies provides all sizes of Weight instrument to suit different uses, so that the length of the Weight instrument ranges from (6 to 24 meters) and the width is (3 meters).

Metal slabs and concrete slabs

The slabs of Weight instrument mean the virtual surface of the scale on which the trucks move directly.

Weight instrument with a metal deck (steel deck) are often set up in factories and workshops, and are characterized by their quick completion and ease of transportation and assembly at the site. However, slip factors must be taken into account in the case of humidity and rain.

Concrete deck Weight instrument of this type are equipped with constructions on site directly.

Weight reading screens

Digital screens are used to read the different weights, and they are also provided with special programs to print the invoice and basic data, and create a database for the weights and goods that are dealt with.

Weight instrument - Weight instrument, also called car scales, are scales used to weigh trucks. It is a truck scale on which the truck stands, and the scale is connected to a computer room that calculates and prints the weight. The goal of truck weighing is when we need to calculate a specific weight. Let's assume a truck of iron and we want to calculate the weight of the iron in this truck. The truck is mounted with iron on the scale and the weight is calculated. Then the empty truck gets on the scale. And the weight is calculated. And we find that the weight of the iron in this case is the weight of the truck with iron less than the weight of the truck without the iron.

What to look for when buying Weight instrument

Are you thinking of buying Weight instrument or upgrading the current scale? There are some simple tips that can help you feel confident in your decision and avoid buyer's remorse.

Download the free Weight instrument Buying Guide

View our free accuracy webinar

Learn about the reliability of Weight instrument

Buying Weight instrument is not an easy task. There are a lot of options to consider, as different companies provide an abundance of information. The truth is that all Weight instrument will perform in approximately the same way and effectively for the first few years after purchase. And whether you buy the cheapest scale or the most expensive one - these scales will work pretty much the same way at first.

As a smart buyer, you will look to the future of your Weight instrument. How much will total ownership cost in 20 years? Here are some things to consider as they greatly affect the true cost of a scale:

Precision

Your Weight instrument act as a cash register for your business. Doesn't it bother you to rip customers off a few bucks in the checkout area on every purchase? With an inaccurate scale, this will be the case. Don't be fooled by marketing that only offers NTAP or ILO testing certifications, these systems allow for a degree of error that will cause you to lose your product to the truckload. Ask for accuracy data, and in case those companies can't provide it to you - cross this company off your list.

reliability

As mentioned above, most Weight instrument will perform nearly as well for the first few years. However, parts start to wear out over time - and with worn and broken parts you incur costly downtime, not to mention service expenses. And every day that goes by and your scales are broken, you incur losses in your business. Make sure your list of questions when buying Weight instrument includes reliability and uptime.

Security

When purchasing a product that should last 20 years or more, warranty is a very important factor to consider. And with a warranty that offers very low insurance coverage, you'll end up incurring more repair expenses over the life of the scale than you paid for the scale in the first place. This is especially true for companies with poor reliability or a high failure rate of load cells. Even if only one or two load cells fail each year, that adds up to thousands of dollars over time.

As a knowledgeable buyer, you can have more confidence when purchasing your Weight instrument and avoid major problems in the future.

Fortunately, there is one company that excels in all of these requirements. METTLER TOLEDO Weight instrument with the POWERCELL® PDX® System give you industry-leading accuracy and reliability, and now offer an industry-leading warranty. Backed by a 10-year warranty on the POWERCELL® PDX® system, you can be confident in your truck scale purchase.

Download the free Weight instrument Buying Guide

View our free accuracy webinar

Learn about the reliability of Weight instrument

(Baskool scales)

Weight instrument are used all over the world, whether in small projects at the level of individuals or large businesses at the level of factories and governments. Weight instrument are used to determine the weight of Weight instrument, or more precisely, the goods loaded on huge trucks.

Determining the weight of the goods loaded on the trucks is considered an important matter, due to the consequent determination of the sale or purchase prices, or the determination of the permitting of trucks to pass on some roads. Therefore, the information and data that are read by scales must be accurate and do not bear any percentage. of mistakes.